Produmex Scan Customization Guide

Customization Technology

The customization process for the Produmex mobile applications consists of the following steps:

- Enable the Customization Assist mode and run the client application. Check the customization information of the screen.

- Create the custom field and/or the SAP user query.

- Restart the client application and check the results of the customization.

Many screens of Produmex mobile applications are customizable with SAP Business One’s queries. The used query have to be named specifically based on the screen it is used on. The query names, and parameters can be found with the help of the 'Customization Assist'. The query result column names indicate which fields to set.

Supported customization types:

- Preset field data

- Validation: The system checks if the entered values are correct during a ‘validate’ or a ‘button’ event.

- Add new fields/Hide existing fields

Helpful Tips and Resources

Click the link below to visit our Article site, where you will find examples and useful information. We are continuously adding new articles featuring the most common customizations.

Produmex Scan Articles: Customization (more subsections are available)

Functional changes introduced in new software releases can impact the behavior of customizations. Customizations are not part of the standard software, and are therefore not tested against new software releases. If you have any customizations, please make sure that appropriate testing protocols are applied to validate the customizations against the new software release.

Enable the Customization Assist

To see information regarding the customization possibilities enable the Customization Assist mode.

Note: The Customization Assist mode is only needed to see customization possibilities. It is not required to be enabled during normal operations.

1. Start the Produmex Scan Configuration application.

2. Enable the Customization Assist Mode setting on the Advanced tab, then press OK to save the setting.

3. Run Produmex Scan and go to the screen that needs to be customized.

4. Tap the C button on the top of the screen.

The Customization screen opens up and it lists the possible parameters for customization with their current value and the customizable events.

Create custom fields

Open the Customization Fields table in SAP Business One via Tools > User-Defined Windows > Customization Fields (BXCUSTFD).

Field Name

The field name will be used to identify the field on the Customization window and in user queries. It is possible to create a new field or to add an existing Produmex Scan field. If the name of an existing field is added, the other properties can be changed.

Example:

In the example we add a custom delivery date field to the Goods Receipt PO screen and we hide the UoM field.

| Field Name | Field Type | Label | Module | Screen | Visible | Ready Only |

|---|---|---|---|---|---|---|

| DELDATE | String | Del.Date | BXMobileWH9 | GoodsReceiptPOLinesScreen | Yes | Yes |

| TextUoM | String | BXMobileWH9 | GoodsReceiptPOLinesScreen | No |

To add data to the fields defined in the Customization Fields user table, use user queries.

It is also possible to add fields that already exist in SAP Business One as a user defined field. In this case no user query is required to copy the values added on the scanner to the database, but additional user queries are needed to populate the fields on the device with the database values.

Add SBO Header Field

Note: This function does not exist on line level.

In order to add an SBO header field, add the DI API field name and the BO_ prefix as the field name on the Customization Fields user table.

Hereinafter you can also change the other properties. When providing the value for Screen, make sure that you indicate the screen from where the final posting process will begin.

Example:

Add the Description field from the SBO Bin Location Master Data form to the Bin Attributes Produmex Scan screen.

| Field Name | Field Type | Label | Module | Screen | Read Only |

|---|---|---|---|---|---|

| BO_Description | String | Description | BXMobileWH9 | BinAttributesScreen | No |

Exception: Field Ref2 must be referenced as BO_Reference2 in the Field Name column.

Add SBO User Defined Field for document header

Note: This function does not exist on line level.

In order to add an SBO user defined field, add the field title with the BO_U_ prefix as the field name on the Customization Fields user table.

Hereinafter you can also change the other properties. When providing the value for Screen, make sure that you indicate the screen from where the final posting process will begin.

Example:

Add the ‘Customer’ user defined field from the SBO Bin Location Master Data form to the Bin Attributes Produmex Scan screen.

| Field Name | Field Type | Label | Module | Screen | Read Only |

|---|---|---|---|---|---|

| BO_U_PMXCUS | String | Customer | BXMobileWH9 | BinAttributesScreen | No |

Add Batch/Serial Number Details

Batch and Serial Number Details has to be added with the following format: #FieldName.

| Title on Batch Details | DB field name | Field Name (CustomizationFields user table) |

|---|---|---|

| Expiration Date | ExpDate | #ExpirationDate |

| Manufacturing Date | MnfDate | #ManufacturingDate |

| Batch Attribute 1 | MnfSerial | #Attribute1 |

| Batch Attribute 2 | LotNumber | #Attribute2 |

| Details | Notes | #Details |

| Title on Serial Number Details | DB field name | Field Name (CustomizationFields user table) |

|---|---|---|

| Expiration Date | ExpDate | #SerialExpirationDate |

| Manufacturing Date | MnfDate | #SerialManufacturingDate |

| Mfr Serial No. | MnfSerial | #SerialAttribute1 |

| Lot Number | LotNumber | #SerialAttribute2 |

| Details | Notes | #SerialDetails |

The default Serial number input field should be the last input field during the data entering process. It is because the Serial number will be added to the list in its validation event.

NOTE: Batch and serial number details are not supported on material return documents and A/R Credit Memos.

Field Type

Type of the field.Supported field types:

- Button(13): Creates a new button. It will have a ‘click’ and ‘click after’ event.

- String(0): Creates a new input field for alphanumeric values. It will have a ‘validate’ and ‘validate after’ event.

- Quantity(5): Creates a new input field. The user can add a number with decimals as the value. It will have a ‘validate’ and ‘validate after’ event.

- Percent(6): Creates a new input field. The user can add a percentage as the value. It will have a ‘validate’ and ‘validate after’ event.

- Integer(8): Creates a new input field. The user can add a whole number as the value. It will have a ‘validate’ and ‘validate after’ event.

- Valid Value Selection(9): Creates a new input field or predefine an already existing input field. The user can add a Valid Value Selection type customization to an input field - ChooseFromList type customization is set for an input field. It will have a ‘validate’ and ‘validate after’ event.

Label

The displayed text. It is also possible the change the label of an existing field.

Module

The name of the mobile solution. Add BXMobileWH9.

On External Form

Defines whether the new field is added to an external screen or not. If you select Yes in the column, a new button (E) is displayed to open the external screen.

Position Data

The position of an object can be changed in this field. Possible values:

- x: - horizontal position (% of screen width from left)

- y: - vertical position (% of screen height from top)

- w: - width (% of screen width)

- h: - height (% of screen height)

- f: - font size (pixel) only on ‘Button’ and for DataRepeater

- lines: - the number of extra lines to be added to the screen, only for DataRepeater

(see section 7. Manipulating DataRepeater / 7.3. Adding extra lines to screens)

Please note that only integer values are allowed. Separate the different parameters with the ‘;’ character.

E.g.: x:1;y:50;w:50;h:80;lines:3

Font size example:

Protected

If it is set to yes, the field is displayed on the next screen as well and the entered value is in read-only mode on this second screen.

Note:

- If a field is customized on a given screen, it cannot be added to the same screen again as a protected field.

- It is recommended to convert the value of the protected field on the second screen in your query because if the field does not contain any value, it can cause any error.

Read Only

Defines whether the field will be read only or not.

Screen

The screen name. The screen name can be found in the first line on the Customization window.

Visible

Defines whether the field is displayed on the screen or not.

Create an SAP user query

Open the Query Manager in SAP Business One via: Tools > Queries > Query Manager

Create the user query.

The name of the query defines when it will be executed, therefore save it as the name of the event when you would like to run the user query.

EXAMPLE: The user query that runs when the ‘GR PO’ screen is loaded in Produmex Scan is 'BXMobileWH9_GoodsReceiptPOScreen_Load'

Supported message types

The following message types can be used in user queries for Produmex Scan:

- I: Information

A pop up information message will be prompted, that needs user confirmation (OK). The event will execute. - E: Error

A pop up error message will be prompted, that needs user confirmation (OK). The event will not execute. - YM: Yes/No with message box

A pop up confirmation message will be prompted, that can be answered with yes or no. The event will execute depending on user choice.

Restart the application

To apply the customization restart the mobile application.

You must restart the application every time a new user query is created but it is not necessary to restart the application when modifying an existing query.

Customization Examples

Goods Receipt PO

Helpful Tips and Resources

Click the link below to visit our Article site, where you will find examples and useful information. We are continuously adding new articles featuring the most common customizations.

Produmex Scan Articles: Customization

Set (user) fields in GR PO

The customization makes possible to set additional fields (SAP or user fields) in the Goods Receipt PO document from.

Go to GR PO Lines screen, and open Customization window. Here you can see the name of this screen: GoodsReceiptPOLinesScreen

To add new fields, open the CustomizationFields User-Defined window in SAP Business One. Use the recommended parameters as below:

| Screen | Module | Label | Field Name | Read Only |

|---|---|---|---|---|

| GoodsReceiptPOLinesScreen | BXMobileWH9 | Del.Date | DELDATE | YES |

Now you are able to load data into this new field. To do it, you have to use the BXMobileWH9_GoodsReceiptPOLinesScreen_Load user query.

If you want to select the delivery date of the purchase order, you will need the purchase order number. You can check the field name on customization screen.

In the example: $[TextPurchaseOrder] = 10 * Mega Supplier LLC

You have to use $[TextPurchaseOrder] field and you have to split the string in the query. If you want to read the data from the field, then you have to use $ character.

SELECT DocDueDate as [DELDATE] FROM OPOR

WHERE DocNum = SUBSTRING( $[TextPurchaseOrder], 0, CHARINDEX('*', $[TextPurchaseOrder], 1) - 1)

Set Freight

It is possible to set the Freight costs/lines in the created Goods Receipt PO with user query. Please see 2.1 Set Freight in Delivery document for the example query.

| UserQuery: bx_mobile_wh9_document_additionalexpenses (Category: BXMobileWH9) | |

|---|---|

| Parameters [%1] - employeeID [%2] - TerminalID [%3] - Head Code from Mobile Transaction table (@BXPLMSMOBTHD.Code) [%4] - grouped Head Codes (string, list), separated with # characters, only applicable for grouped Purchase Order/APReserve invoice → Goods Receipt PO | Results Zero, one or more rows for the Freight charges to be created. The result columns can have the names: * BO_LineTotal = the LineTotal field, amount of money (mandatory) * BO_ExpenseCode = Expense Code (integer) (mandatory) |

Batch number generation

On some screens (e.g. Goods Receipt PO, Receipt from Production) the system can automatically generate batch numbers when entering the received quantities and bin locations. The batch number generation logic can be defined in a user query.

| UserQuery: bx_mobile_wh9_get_new_batchnumber (Category: BXMobileWH9) | |

|---|---|

| Parameters [%1]: employee ID (int) [%2]: terminal ID (nvarchar) [%3]: base document type (int) [%4]: base document entry (int) [%5]: base document line (int) [%6]: item code (nvarchar) | Results The user query should return the batch number in a column called BXBATNUM (type of the field should be NVARCHAR) |

Note: The standard click and click_after events cannot use the parameters of the bx_mobile_wh9_get_new_batchnumber query.

Example:

The following query generates a batch number combining the supplier code and the current date:

SELECT T0.[CardCode] + '-' + CONVERT(varchar, GETDATE(), 112) AS 'BXBATNUM' FROM OPOR T0 WHERE T0.[DocEntry] = [%4]

Serial number generation

In the Goods Receipt PO process, the system can automatically generate serial numbers when entering the received stocks. The serial number generation logic needs to be defined in a user query.

| UserQuery: bx_mobile_wh9_get_new_serialnumber (Category: BXMobileWH9) | |

|---|---|

| Parameters [%1]: employee ID (int) [%2]: terminal ID (nvarchar) [%3]: base document type (int) [%4]: base document entry (int) [%5]: base document line (int) [%6]: item code (nvarchar) | Results The user query should return as single serial number in a column called BXSERNUM. Note: If the query returns more than one row, the first row's value will be used. |

Expiration date at GRPO/Inventory

The following fields can be used at BatchScreen or SerialScreen:

BATCH_EXPIRATION_DATE = “#ExpirationDate”;

BATCH_MANUFACTURING_DATE = “#ManufacturingDate”;

BATCH_ATTRIBUTE1 = “#Attribute1”;

BATCH_ATTRIBUTE2 = “#Attribute2”;

BATCH_DETAILS = “#Details”;

SERIAL_EXPIRATION_DATE = “#SerialExpirationDate”;

SERIAL_MANUFACTURING_DATE = “#SerialManufacturingDate”;

SERIAL_ATTRIBUTE1 = “#SerialAttribute1”;

SERIAL_ATTRIBUTE2 = “#SerialAttribute2”;

SERIAL_DETAILS = “#SerialDetails”;

These fields can be added on the CustomizationFields table.

Example for batches:

| Field Name | Label | Screen |

|---|---|---|

| #ExpirationDate | BBD | ReceiptFromProductionQuantitiesBatchScreen |

| #ManufacturingDate | ManufacturingDate | ReceiptFromProductionQuantitiesBatchScreen |

| #ExpirationDate | BBD | GoodsReceiptPOQuantitiesBatchScreen |

2.1.6. Generate GRPO from Draft

Note: This customization is compatible from SAP Business One version 2405 or later versions. It will not function on earlier versions!

With this customization GRPOs can be created from draft. When starting the Goods Receipt Purchase Order function on the scanner and there is a draft GRPO registered in SBO for the given warehouse, the draft document is listed among the Purchase Orders.

The 'Post' button is immediately active for draft documents when selected and the 'Receive' button is hidden/not available. When the 'Post' button is pressed while a GRPO draft is selected, the GRPO is created from the GRPO draft with the exact same stock parameters as the GRPO draft.

Note: DR = draft GRPO (new), PO = Purchase Order, RI = A/P Reserve Invoice

UserQuery: bx_mobile_wh9_goodsreceiptpo_query_custom

SELECT

Distinct "DocEntry", "DocType", ItemCode

FROM (

SELECT "OPOR"."DocEntry", 22 as "DocType", "CardCode", "DocNum", "DocDueDate", "POR1"."ItemCode" FROM "POR1" LEFT JOIN "OPOR" ON "POR1"."DocEntry" = "OPOR"."DocEntry" WHERE "DocStatus" = 'O'

UNION

SELECT "OPCH"."DocEntry", 18 as "DocType", "CardCode", "DocNum", "DocDueDate", "PCH1"."ItemCode" FROM "PCH1" LEFT JOIN "OPCH" ON "PCH1"."DocEntry" = "OPCH"."DocEntry" WHERE "DocStatus" = 'O'

UNION

SELECT "ODRF"."DocEntry", 20 as "DocType", "CardCode", "DocNum", "DocDueDate", "DRF1"."ItemCode" FROM "DRF1" LEFT JOIN "ODRF" ON "DRF1"."DocEntry" = "ODRF"."DocEntry" WHERE "ODRF"."ObjType" = '20' AND "DocStatus" = 'O' AND "ODRF"."WddStatus" in ('Y','')

) as DOCUMEND

WHERE

(CASE WHEN isnull($[ItemCode], '') = '' THEN 1 ELSE CASE WHEN "DOCUMEND"."ItemCode" = $[ItemCode] THEN 1 ELSE 0 END END) = 1

AND (CASE WHEN isnull($[DocNum], '') = '' THEN 1 ELSE CASE WHEN "DOCUMEND"."DocNum" = $[DocNum] THEN 1 ELSE 0 END END) = 1

AND (CASE WHEN isnull($[CardCode], '') = '' THEN 1 ELSE CASE WHEN "DOCUMEND"."CardCode" = $[CardCode] THEN 1 ELSE 0 END END) = 1

AND (CASE WHEN isnull($[DueDate], '') = '' THEN 1 ELSE CASE WHEN "DOCUMEND"."DocDueDate" = $[DueDate] THEN 1 ELSE 0 END END) = 1

Implementation:

Add the query in the Query Manager in SBO

Sales Orders

Set Freight in Delivery document

By default the Freight in the created Delivery document is 0. It is possible to customize Produmex Scan so freight lines are added with a custom freight calculation algorithm. This algorithm receives a parameter which allows to query the items, quantities, base documents which will be used to create the new Delivery Document.

| UserQuery: bx_mobile_wh9_document_additionalexpenses (Category: BXMobileWH9) | |

|---|---|

| Parameters [%1] - employeeID [%3] - Head Code from Mobile Transaction table (@BXPLMSMOBTHD.Code) [%4] - grouped Head Codes (string, list), separated with # characters, only applicable for grouped Purchase Order/APReserve invoice → Goods Receipt PO | Results Zero, one or more rows for the Freight charges to be created. The result columns can have the names: BO_LineTotal = the LineTotal field, amount of money (mandatory) BO_ExpenseCode = Expense Code (integer) (mandatory) |

Example:

A combined query to copy expenses from Sales Orders and Purchase Orders.

Query name: bx_mobile_wh9_document_additionalexpenses

declare @salesOrderDocEntry int SELECT @salesOrderDocEntry = U_BXPBsDcE FROM [@BXPLMSMOBTLN] WHERE U_BXPHdCd = [%3] AND U_BXPBsDcT = 17 AND U_BXPDocTy = 15 -- 15-delivery, 17-sales order IF @salesOrderDocEntry > 0 BEGIN SELECT ExpnsCode as BO_ExpenseCode, LineTotal as BO_LineTotal, 17 as BO_BaseDocType, @salesOrderDocEntry as BO_BaseDocEntry, LineNum as BO_BaseDocLine FROM RDR3 WHERE DocEntry = @salesOrderDocEntry AND Status <> 'C' END declare @purchaseOrderDocEntry int SELECT @purchaseOrderDocEntry = U_BXPBsDcE FROM [@BXPLMSMOBTLN] WHERE U_BXPHdCd = [%3] AND U_BXPBsDcT = 22 AND U_BXPDocTy = 20 -- 22-Purchase order, 20-Goods Receipt PO IF @purchaseOrderDocEntry > 0 BEGIN SELECT ExpnsCode as BO_ExpenseCode, LineTotal as BO_LineTotal, 22 as BO_BaseDocType, @purchaseOrderDocEntry as BO_BaseDocEntry, LineNum as BO_BaseDocLine FROM POR3 WHERE DocEntry = @purchaseOrderDocEntry AND Status <> 'C' END

HANA version

CREATE PROCEDURE PMXSCAN_ADDITIONALEXPENSES (

IN

pHeadCode NVARCHAR(5000)

)

LANGUAGE SQLSCRIPT

AS

BEGIN

declare purchaseOrderDocEntry int;

declare salesOrderDocEntry int;

SELECT SUM("U_BXPBsDcE") into salesOrderDocEntry FROM

(

SELECT 0 "U_BXPBsDcE" FROM DUMMY

UNION

SELECT "U_BXPBsDcE"

FROM "@BXPLMSMOBTLN"

WHERE "U_BXPHdCd" = pHeadCode AND "U_BXPBsDcT" = 17 AND "U_BXPDocTy" = 15

);

-- 15-delivery, 17-sales order

IF salesOrderDocEntry > 0 THEN

SELECT

"ExpnsCode" as "BO_ExpenseCode",

"LineTotal" as "BO_LineTotal",

17 as "BO_BaseDocType",

salesOrderDocEntry as "BO_BaseDocEntry",

"LineNum" as "BO_BaseDocLine"

FROM "RDR3"

WHERE "DocEntry" = salesOrderDocEntry AND "Status" <> 'C';

END IF;

SELECT SUM("U_BXPBsDcE") into purchaseOrderDocEntry FROM

(

SELECT 0 "U_BXPBsDcE" FROM DUMMY

UNION

SELECT "U_BXPBsDcE"

FROM "@BXPLMSMOBTLN"

WHERE "U_BXPHdCd" = pHeadCode AND "U_BXPBsDcT" = 22 AND "U_BXPDocTy" = 20

);

-- 22-Purchase order, 20-Goods Receipt PO

IF purchaseOrderDocEntry > 0 THEN

SELECT

"ExpnsCode" as "BO_ExpenseCode",

"LineTotal" as "BO_LineTotal",

22 as "BO_BaseDocType",

purchaseOrderDocEntry as "BO_BaseDocEntry",

"LineNum" as "BO_BaseDocLine"

FROM "POR3"

WHERE "DocEntry" = purchaseOrderDocEntry AND "Status" <> 'C';

END IF;

END;

SAP Query name:

bx_mobile_wh9_document_additionalexpenses

content:

call "PMXSCAN_ADDITIONALEXPENSES"( [%3] );

This example user query looks at the Mobile Transaction (lines) table, filters for Base Document Type = Sales Order, finds the base Sales Order Document DocEntry. It then retrieves the freight expense records related to the Sales Order (from table RDR3), and extracts Expense Code and Line Total, so it essentially copies all the freight charges from the Sales Order without any calculation.

Packing ID

It is possible to record packaging ID during picking. The package ID screen can be added to the picking lines screen.

Example:

| Field Name | Label | Screen |

|---|---|---|

| #PackageId | Package ID | PickingLinesPickNormalScreen |

| #PackageId | Package ID | PickingLinesPickBatchScreen |

| #PackageId | Package ID | PickingLinesPickSerialScreen |

The Package ID is automatically filled with the last Package ID value that was added for the pick list. Both numbers and letters are supported in this field.

The package ID is stored on the MobilePickingData (BXPLMSMOBPICK) user table.

Pick Lists

Set Freight in Delivery

Please see: 2.1 Set Freight in Delivery document

Set (user) fields in Delivery

It is possible to set the values of the Delivery Document which are created from the Produmex Scan Pick List screen.

To set a field, you have to add a customization field to the Pick List Lines screen. The customization field name must be:

- BO_U_XXField1 to set Delivery Document U_XXField1 custom field

- BO_FieldName to set Delivery Document SAP internal field by API name. In this case, the field name must match the DI API name. Example: BO_JournalMemo

In the Customization Fields user table, it is important that the Field Name is BO_U_*and it must match the UDF name (with a U_Prefix), eg. BO_U_Test1 → Test1 userdefined field. The Label can be anything.

Example:

| Screen | Module | Label | Field Name |

|---|---|---|---|

| PickingLinesScreen | BXMobileWH9 | Test 1 | BO_U_Test1 |

| PickingLinesScreen | BXMobileWH9 | Test 2 | BO_U_Test2 |

When pressing the Delivery button on the Pick List lines screen, these field values will be used in the newly created Delivery Document.

Pick List screen - customize list

With the default settings, only open pick lists that have not been started by anyone are displayed, but the original program logic can be overridden by customization.

| UserQuery: bx_mobile_wh9_picklists_query_custom (Category: BXMobileWH9) | |

|---|---|

| Parameters $[AbsEntry] $[CardCode] $[EmployeeNo] - logged in employeeID $[ItemCode] $[PickDate] $[WarehouseCode] | Results A table with multiple rows with a single column (integer) with PickList AbsEntry values. (OPKL.AbsEntry) |

Example:

With the example user query the list of picklists is filtered down to picklist assigned to the employee. We used the ‘Picker’ field on the Pick list to assign the employee to the pick list.

Please note: The Picker field must be in the 'FirstName LastName' or 'FirstName MiddleName LastName' format for the example user query to work.

The example user query name: bx_mobile_wh9_picklists_query_custom

IF $[AbsEntry] IS NOT NULL BEGIN SELECT AbsEntry FROM OPKL WHERE AbsEntry = $[AbsEntry] AND Status <> 'C' END ELSE BEGIN SELECT AbsEntry FROM OPKL WHERE Name = (SELECT firstName + ' ' + ISNULL(middleName + ' ', '') + lastName FROM OHEM WHERE empID = $[EmployeeNo]) AND Status <> 'C' ORDER BY AbsEntry END

This simple example only filters for employee or PickListNo, but doesn't respect other filters like Customer, Item, DueDate, Warehouse. It also allows the employee to enter a PickListNo and allows him to select that pick list even if he's not assigned for it.

Auto fill batch with recommended batch

To automatically populate the Batch field with the recommended batch, add the following query:

Query name: BXMobileWH9_PickingLinesPickBatchScreen_Activate

SELECT $[TextRecBatch] AS [TextBatch]

Capture pick list selection events into a separate table

It is possible to capture the date and time when an employee selects a pick list into a separate table.

Create the user table

First create the user table for the pick list selection events. Example: PMX_PLLOG user table

Set the object type to ’No object with Auto.Increment’.

Add the user defined fields to the table. In the example we will add the following fields:

| Title | Description | Type |

|---|---|---|

| Date | Date | Date/Time |

| Time | Time | Numeric |

| EmpID | Employee ID | Alphanumeric |

| EmpName | Employee Name | Alphanumeric |

| PLN | Pick List | Numeric |

Create the user query

The user query name is: BXMobileWH9_PickingScreen_OK_clicked

SQL

INSERT INTO "@PMX_PLLOG" ("Name", "U_Date", "U_Time", "U_EmpID", "U_EmpName", "U_PLN")

values ('Pick List Entry', cast(getdate() as date), cast(substring(CONVERT(VARCHAR,GETDATE(),108),1,2) * 100 + substring(CONVERT(VARCHAR,GETDATE(),108),4,2) as int), $[Employee.EmployeeID], $[Employee.FirstName]+ ' '+ $[Employee.LastName], SUBSTRING($[DataRepeater.SelectedUIPickListNo], CHARINDEX('#', $[DataRepeater.SelectedUIPickListNo]) + 1, LEN($[DataRepeater.SelectedUIPickListNo]) - CHARINDEX('#', $[DataRepeater.SelectedUIPickListNo])))

HANA

INSERT INTO "@PMX_PLLOG" ("Name", "U_Date", "U_Time", "U_EmpID", "U_EmpName", "U_PLN")

values ('Pick List Entry', cast(getdate() as date), cast(substring(CONVERT(VARCHAR,GETDATE(),108),1,2) * 100 + substring(CONVERT(VARCHAR,GETDATE(),108),4,2) as int), $[Employee.EmployeeID], $[Employee.FirstName]+ ' '+ $[Employee.LastName], SUBSTRING($[DataRepeater.SelectedUIPickListNo], LOCATE($[DataRepeater.SelectedUIPickListNo], '#') + 1) FROM DUMMY´)

When the 'Pick' button is pressed, this query inserts the current date to the Date column, the current time to the Time column, the employee ID to the Employee ID column, the first and last name of the employee to the Employee Name column and the pick list number to the Pick List column.

Query Stocks

Override list

It is possible to override the list of items on the Query Stocks screen.

This is the same screen that can be opened from Pick List and from other modules in Produmex Scan when pressing the Find Stocks button, so the custom logic is also relevant for those cases.

| UserQuery: bx_mobile_wh9_querystocks_query_custom (Category: BXMobileWH9) | |

|---|---|

| Parameters $[Warehouse] $[BinLocation] $[ItemCode] $[BatchNumber] ($[..] - other user fields from screen) | Results A table with multiple rows with specific column names: - Warehouse - BinLocation - ItemCode - ItemName - ManagedBy (Batch: 10000044, Serial: 10000045, None: -1) - OnHandQuantity (in inventory UoM) |

Example:

This custom query returns items sorted by quantity (descending).

Please note: This query doesn't filter by batch input parameter, only Warehouse, ItemCode and BinLocation.

Query name: bx_mobile_wh9_querystocks_query_custom

-- return maximum 20(+20) matches by filters, ordered by quantity descending -- first select is for bin-activated warehouses SELECT TOP 20 OIBQ.WhsCode as Warehouse, OBIN.BinCode as BinLocation, OIBQ.ItemCode, OITM.ItemName, CASE WHEN OITM.ManSerNum = 'Y' THEN 10000045 WHEN OITM.ManBtchNum = 'Y' THEN 10000044 ELSE -1 END as ManagedBy, OIBQ.OnHandQty as OnHandQuantity FROM OIBQ JOIN OBIN ON (OBIN.AbsEntry = OIBQ.BinAbs) JOIN OITM ON (OITM.ItemCode = OIBQ.ItemCode) WHERE (OIBQ.ItemCode = $[ItemCode] OR $[ItemCode] = '') AND (OIBQ.WhsCode = $[Warehouse] OR $[Warehouse] = '') AND (OBIN.BinCode = $[BinLocation] OR $[BinLocation] = '') AND OnHandQty > 0 UNION -- this second select is for non-bin warehouses SELECT TOP 20 OITW.WhsCode as Warehouse, '' as BinLocation, OITW.ItemCode, OITM.ItemName, CASE WHEN OITM.ManSerNum = 'Y' THEN 10000045 WHEN OITM.ManBtchNum = 'Y' THEN 10000044 ELSE -1 END as ManagedBy, OITW.OnHand as OnHandQuantity FROM OITW JOIN OITM ON (OITM.ItemCode = OITW.ItemCode) JOIN OWHS ON (OWHS.WhsCode = OITW.WhsCode) WHERE OWHS.BinActivat = 'N' AND (OITW.ItemCode = $[ItemCode] OR $[ItemCode] = '') AND (OITW.WhsCode = $[Warehouse] OR $[Warehouse] = '') -- order by quantity descending ORDER BY OnHandQuantity DESC

General for multiple processes

Creating documents as drafts

It is possible to control whether the documents should be created as drafts or as real documents when posted from Produmex Scan for the following documents:

| Document | Doc. type |

|---|---|

| Delivery | 15 |

| Sales Order (by BN Create SO function) | 17 |

| Goods Receipt PO | 20 |

| Goods Issue | 60 |

The controlling logic must be defined with a user query.

| UserQuery: bx_mobile_wh9_document_creation_type (Category: BXMobileWH9) | |

|---|---|

| Parameters [%1]: employee ID (int) [%3]: mobile transaction head code (nvarchar) | Results The user query should return the result in a column called BXDOCTYP. The result must be an integer, and the following values are supported: - 0: real document - 1: draft |

For example, with the following logic, all goods receipt PO documents (doc. type = 20) will be created as drafts, while the other documents are created as real documents:

MS SQL

SELECT CASE T0.[U_BXPDocTy] WHEN 20 THEN 1 ELSE 0 END as 'BXDOCTYP' FROM [dbo].[@BXPLMSMOBTHD] T0 WHERE T0.[Code] = [%3]

HANA

SELECT case T0."U_BXPDocTy" when 20 then 1 else 0 end as "BXDOCTYP" FROM "@BXPLMSMOBTHD" T0 WHERE T0."Code" = [%3]

2.5.2.Special field for series numbering

A user field for series numbering can be added to screens where a Post event starts.

Field name: BO_Series

Example: Add a user field for numbering series to the GR PO screen

Add the following record to the Customization Fields user table:

| Screen | Module | Label | Field Name | Read Only |

|---|---|---|---|---|

| GoodsReceiptPOPostSelectionScreen | BXMobileWH9 | Series numbering | BO_Series | No |

2.5.3.Capture login events into a separate table

It is possible to capture the date and time of the employee login and logout events in a separate user table.

Create the user table

First create the user table for the log in and log out events. Example: PMX_EMPLOG user table

Set the object type to ’No object with Auto.Increment’.

Add the user defined fields to the table. In the example we will add the following fields:

| Title | Description | Type |

|---|---|---|

| Date | Date | Date/Time |

| Time | Time | Numeric |

| EmpID | Employee ID | Alphanumeric |

| EmpName | Employee Name | Alphanumeric |

Create the user query

The user query name for the log in is: BXMobileWH9_LoginScreen_OK_clicked

SQL

INSERT INTO "@PMX_EMPLOG" ("Name", "U_Date", "U_Time", "U_EmpID", "U_EmpName")

values ('Login', cast(getdate() as date), cast(substring(CONVERT(VARCHAR,GETDATE(),108),1,2) * 100 + substring(CONVERT(VARCHAR,GETDATE(),108),4,2) as int), $[TextUser], $[TextUserName])

HANA

INSERT INTO "@PMX_EMPLOG" ("Name", "U_Date", "U_Time", "U_EmpID", "U_EmpName")

values ('Login', cast(current_timestamp as date), TO_INT( TO_VARCHAR( CURRENT_TIMESTAMP, 'HH24MI' ) ), $[TextUser], $[TextUserName])

This query inserts the current date to the Date column, the current time to the Time column, the employee ID to the Employee ID column, the first and last name of the employee to the Employee Name column and the event name in the Name column.

Special customization

You can use this special customization to manipulate the loaded data.

Special customization queries

Query Stocks

| User query: bx_mobile_wh9_querystocks_query_custom | |

|---|---|

| Parameters $[ItemCode], $[Warehouse] | Query fields Warehouse, BinLocation, ItemCode, ItemName, ManagedBy, OnHandQuantity |

This example will order the result by batch number.

SELECT TOP 20 OIBQ.WhsCode as Warehouse, OBIN.BinCode as BinLocation, OIBQ.ItemCode, OITM.ItemName,

CASE

WHEN OITM.ManSerNum = 'Y' THEN 10000045

WHEN OITM.ManBtchNum = 'Y' THEN 10000044

ELSE -1 END as ManagedBy, OIBQ.OnHandQty as OnHandQuantity

FROM OIBQ

JOIN OBIN ON (OBIN.AbsEntry = OIBQ.BinAbs)

JOIN OITM ON (OITM.ItemCode = OIBQ.ItemCode)

JOIN OBBQ ON (OBBQ.BinAbs = OIBQ.BinAbs)

JOIN OBTN ON (OBBQ.SnBMDAbs = OBTN.AbsEntry)

WHERE

(OIBQ.ItemCode = $[ItemCode] OR $[ItemCode] = '')

AND (OIBQ.WhsCode = $[Warehouse] OR $[Warehouse] = '')

AND (OBBQ.ItemCode = $[ItemCode] OR $[ItemCode] = '')

AND (OBBQ.WhsCode = $[Warehouse] OR $[Warehouse] = '')

AND OIBQ.OnHandQty > 0

AND OBBQ.OnHandQty > 0

ORDER BY OBTN.DistNumber

2.6.1.2. Picklist

| User query: bx_mobile_wh9_picklists_query_custom | |

|---|---|

| Parameters $[AbsEntry], $[CardCode], $[EmployeeNo], $[ItemCode], $[PickDate], $[WarehouseCode], $[BinLocationCode] | Query fields AbsEntry |

On the pick list screen, you can use custom fields in the custom query.

Example:

Add a new custom field ’CFEmpID’ for employee input on the CustomizationFields table.

| Field Name | Label | Screen |

|---|---|---|

| CFEmpID | EmpID | PickingScreen |

After the field is added it can be used in a custom query. Query name: bx_mobile_wh9_picklist_query_custom

IF ($[CFEmpID]='') BEGIN SELECT AbsEntry FROM OPKL WHERE Status <> 'C' ORDER BY AbsEntry desc END ELSE BEGIN SELECT AbsEntry FROM OPKL WHERE Status <> 'C' AND U_BXPEmpID=$[CFEmpID] ORDER BY AbsEntry desc END

Sales order lines

| User query: bx_mobile_wh9_salesorderlines_query_custom | |

|---|---|

| Parameters $[DocEntry] | Query fields LineNum, BinCode |

Sales issue

| User query: bx_mobile_wh9_salesissue_query_custom | |

|---|---|

| Parameters $[DocNum], $[CardCode], $[DueDate], $[ItemCode], $[EmployeeNo] | Query fields DocEntry, DocType (17:Sales Order; 13:A/R Reserve invoice) |

Goods Receipt PO

| User query: bx_mobile_wh9_goodsreceiptpo_query_custom | |

|---|---|

| Parameters $[DocNum], $[CardCode], $[DueDate], $[ItemCode], $[EmployeeNo] | Query fields DocEntry, DocType (18:A/P Reservere invoice; 22: Purchase Order) |

Stock Transfer Request

| User query: bx_mobile_wh9_stocktransferrequest_query_custom | |

|---|---|

| Parameters $[DocNum] $[WarehouseFrom] $[WarehouseTo] | Query fields DocEntry |

Stock Transfer Request Lines

| User query: bx_mobile_wh9_stocktransferrequestlines_query_custom | |

|---|---|

| Parameters $[DocEntry] | Query fields LineNum IsAvailable |

Customize The order of the pick list lines

This query is designed to work with both Speed Picking and Sequential Picking processes. In both cases, the system will place the picked items at the end of the list without reloading the entire item list. This behavior is intentional and should remain the standard for these picking logics to maintain consistency and efficiency.

Important Note: The “PickEntry” field and the “Order” alias are mandatory and must be used!

| User query: bx_mobile_wh9_picklistlines_query_custom | |

|---|---|

| Parameters $[AbsEntry] | Query fields PickEntry AS “Order” |

IF $[AbsEntry] IS NOT NULL BEGIN SELECT PickEntry AS "Order" FROM PKL1 WHERE AbsEntry = $[AbsEntry] ORDER BY RelQtty DESC, PickEntry DESC END

Button customization

Example:

Automatically click on the ‘Reload’ button after scanning on the GR PO screen.

Query name: BXMobileWH9_GoodsReceiptPOScreen_TextDocumentNumber_validate_after

IF $[TextDocumentNumber] <> '' BEGIN SELECT 'ButtonReload' as 'Click$' END

The name of the button can be found in customization assist. A custom button also can be pressed. The two buttons at the bottom of the screen are called 'OK' and 'Option'

Custom message

You can send a message to employee is a custom event.

SELECT 'Information' as "Message$", 'I' as "MessageType$"

HANA version:

SELECT 'Information' as "Message$", 'I' as "MessageType$" FROM DUMMY

See the supported message types here: Supported message types

Other Examples

Populate Bin Location field with default item locaion in GR PO

You have to add the same query content for all item types

Query names:

BXMobileWH9_GoodsReceiptPOQuantitiesNormalScreen_Load BXMobileWH9_GoodsReceiptPOQuantitiesBatchScreen_Load BXMobileWH9_GoodsReceiptPOQuantitiesSerialScreen_Load

select "OBIN"."BinCode" as "TextBinLocation" from "OITW" LEFT JOIN "OBIN" on "OITW"."DftBinAbs" = "OBIN"."AbsEntry" where "OITW"."ItemCode" = $[SelectedPurchaseOrderLine.ItemCode] and "OITW"."WhsCode" = $[SelectedPurchaseOrderLine.WarehouseCode]

2.7.2. Delete the document number in screen load event in GR PO Screen

You have to add an SAP query with the name of the screen load event Query names:

BXMobileWH9_GoodsReceiptPOScreen_Load

select '' as "TextDocumentNumber"

Auto print Delivery in Sales Issue process

It is possible to use the ButtonPost_click_after event to trigger the printing. The SAP document is already created in this event. The number of the new Delivery is not available in the customization, so we can only print the last Delivery document that was created by the logged in employee.

You can see the configuration steps below.

- Locate the Delivery note from the “Report and Layout Manager”

- Open it in Crystal Reports Designer.

- Set the database configuration for the report file and save a copy from the report.

- Check the paramters of the report file, we need them in the custom query.

-import the report file into SBO by function “Report and Layout Manager”

- Create the custom query

- Use the SBO Report ID in column: “PrintLayout$”

- Set all properties in a new column by addind “Print_” prefix

- Set the printer name in column: “PrintPrinter$”

- Send a message about the printing in columns “Message$” and “MessageType$”

SELECT TOP 1 'RCRI0013' as "PrintLayout$", "DocEntry" as "Print_DocKey@", 15 as "Print_ObjectId@", 'Bullzip PDF Printer' as "PrintPrinter$", 'Delivey is Printed' "Message$", 'I' "MessageType$" FROM "ODLN" WHERE "U_BXPEmpID" = $[Employee.EmployeeID] ORDER BY "DocEntry" DESC

- The name od the query must be: BXMobileWH9_SalesIssueScreen_ButtonPost_click_after

- Produmex Scan application must be restarted after adding the new customization

- Since the report file contains sub reports you may enable it in the setting below. You can find more information about this setting on the url below

Advanced printing configurations

In the Picking process you can use the query name below:

BXMobileWH9_PickingLinesScreen_ButtonDeliver_click_after

The PickingLineScreen will be closed after createing the Delivery and the event won't be able to use objects from the PickingLineScreen anymore. It is necessary to check the setting below in order to prevent closing the screen.

“Don't close screen after picking delivery”

Capture GRPO Images

Overview

The Image Capture allows Produmex Scan to attach photos directly to incoming logistics documents such as Goods Receipt PO and Sales Return.

Captured images are:

- Saved into SAP’s Attachment system using a structured file name format.

- Linked in Produmex Scan internal tables for reference (note: after posting, the file path is no longer stored in the Scan table).

Supported document flows:

- GRPO

- Free GRPO

- Sales Returns (SDN and SRR)

How Image Capture Works

When enabled, users can take one or more pictures directly from the scanning flow. Images are validated, saved to SAP’s attachment path, and linked to the document line.

The Image Capture process has three major steps:

- When a picture is taken, it is stored in the device’s memory.

- When the entry is created, the image is saved to the database.

- After the document is posted, the image is saved as a JPG file in the attachments folder and then it will be removed from the database.

The capture behavior depends on the warehouse setup and item type:

| Warehouse / Item Type | Capture Location |

|---|---|

| Bin-managed warehouse | Detail screen (bin/batch/serial screen) |

| Non-bin-managed warehouse + batch/serial item | Batch/serial detail screen |

| Non-bin-managed warehouse + normal item | Line screen (when line is selected) |

GR PO - Image Capturing is enabled on the Mobile Client:

Produmex Scan Settings

An additional setting for the image capturing called Produmex Scan Media is available on the Add-On’s Settings screen.

This tab allows users to configure:

- Capturing behavior

- File naming conventions

- Image limits

Attachment file name format

- Default: <UserName>_<DocEntry>_<LineNum>_<BatchOrSerial>_<Timestamp>.jpg

- Defines how each attachment file is named. Unsupported characters or spaces are automatically replaced with underscores (_).

- The file name must include the following placeholders: <UserName>, <DocEntry>, <LineNum>, and <Timestamp>

- The order of the placeholders can be changed, and additional text can be added to the file name.

- <BatchOrSerial> is optional.

- <UserName> = Employee ID.

- <Timestamp> = UTC datetime or any other datetime that was set.

- .jpg is required.

Attachment maximum file size (MB)

- Default: 3 MB

- It can be modified, images larger than the set limit cannot be captured or uploaded.

Capture images for incoming documents

- Default: Unchecked

- When enabled, image capture becomes available for GRPO, Free GRPO, and Sales Returns flows.

Maximum number of attached images per incoming document

- Default: 20

- Restricts the total number of photos per document.

Show preview when capturing images

- Default: Checked

- The CameraApp will always display a preview before saving, regardless of this setting.

Once the document is posted, the physical file is saved under SAP General Settings → Path for Attachments. The file name is generated using the defined template, and Produmex Scan stores the final file path in its internal tables.

Valid Value Selection Screen

Overview

The Valid Value Selection Screen allows custom Produmex Scan screens to replace free-text inputs with predefined, easy-to-select values. The selection screen can be applied to an existing input field or added as a new field, and is fully supported on both Android and Windows Mobile devices.

How the Valid Value Selection Screen Works

The valid value selection screen uses Valid Values to populate the selectable list.

The Default Value field specifies which key should be preselected when the screen loads.

Optional user queries can fully override the valid values or default value:

- BXMobileWH9_<ScreenName>_<ControlName>_<InternalDataLoad> - Returns the list of valid values.

- BXMobileWH9_<ScreenName>_<ControlName>_<DefaultValue> - Returns the default value key.

Note: If these queries are defined, their results take priority over the standard field configuration.

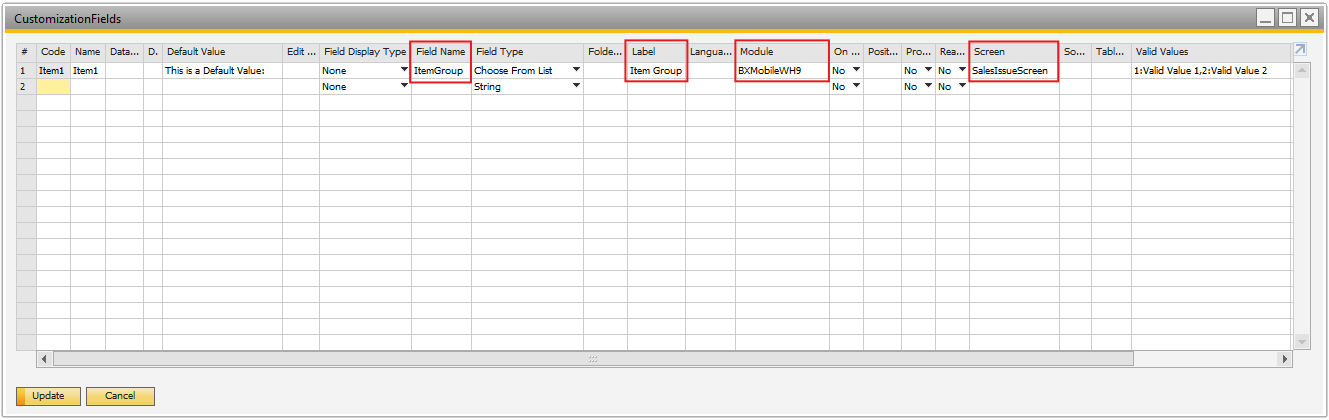

How to Create a Customized Valid Value Selection Screen

1. Open Customization Fields

- In SAP Business One, navigate to: Produmex Scan → Customization → Customization Fields

2. Set Field Type to Choose from List

In the Field Type column, select Choose from List. This tells Produmex Scan to use a Choose from List instead of a text field.

3. Define Valid Values

The user can define valid values in either of the following ways:

- Option A - Enter key-value pairs directly

- Use the Valid Values field and provide pairs in the format: KEY1:Value 1,KEY2:Value 2,KEY3:Value 3

- Example: 1:Valid Value 1,2:Valid Value 2

- Option B - Use a user query

- Enter the name of an SAP user query

- If the query BXMobileWH9_<ScreenName>_<ControlName>_load_values is defined, it will override the field, the load_values query is used to retrieve the valid values. The query must return a key–value pair, and the returned value will be used as the default.

Filtering Sales Orders by Item Group

This example shows how the Valid Value Selection screen can be used to filter Sales Orders based on Item Groups.

Based on the example image let's create a custom query that contains the following:

- Field Name: ItemGroup

- Label: Item Group

- Module: BXMobileWH9

- Screen: SalesIssueScreen

Step 1: Displaying a List of Valid Values

Select a list of valid values that will be displayed:

Open the Query Manager and create a query:

Open the Query Manager and create a query:

BXMobileWH9_SalesIssueScreen_ItemGroup_load_values

Insert the content:

select

ItmsGrpCod as "Key",

ItmsGrpNam as "Value"

from OITB

Step 2: Selecting and saving a Value from the List

When the user selects an Item Group from the Valid Value Selection Screen:

- The selected Item Group Code is stored by the system

- This stored value is later used to filter Sales Orders

Open the Query Manager and create a query:

BXMobileWH9_SalesIssueScreen_ItemGroup_validate

Insert the content:

UPDATE OHEM SET U_TEST = $[ItemGroup] WHERE "empID" = $[Employee.EmployeeID]

Step 3: Reloading the Sales Order Screen

Pressing Reload will show:

- Open Sales Orders

- Only those Sales Orders that contain items from the selected Item Group

Open the Query Manager and create a query:

bx_mobile_wh9_salesissue_query_custom

Insert the content:

select distinct

RDR1.DocEntry,

17 as DocType

from RDR1

left join OITM on RDR1.ItemCode = OITM.ItemCode

left join ORDR on ORDR.DocEntry = RDR1.DocEntry

where

LineStatus = 'O'

and OITM.ItmsGrpCod in (

select U_TEST

from OHEM

where empID = $[EmployeeNo]

)

Step 4: Save and see the result

The Valid Value Selection Screen provides a simple and reliable way to:

- Display a list of valid values from the database

- Let users select a value instead of typing manually

- Save the selected value

- Automatically filter data on other screens

4. Set a Default Value

The user can define a default value in one of the following ways:

- Option A – Manual Default Value

- In the Default Value field, you can manually enter the text that should be displayed.

- Example: “This is a Default Value”

- Option B – Using a User Query

- A default value can be provided using a user query. The query can be the following for example: BXMobileWH9_<SalesIssueScreen>_<ItemGroup>_load_default_value

Customization Example: Micro-Vertical Solution for Serial Numbered Appliance Trading Organizations

This document describes how the Free Goods Receipt PO process in Produmex Scan was customized to fit a typical client and form a part of the micro-vertical solution for serial numbered appliance trader and similar companies. The customizations for each screen are described in detail.

Free Goods Receipt PO

In Produmex Scan, the Free Goods Receipt PO consist of 3 screens: a main screen used to start creating and preparing a new Goods Receipt document, a screen showing item lines and quantities and a detail screen on which the receiving bin location and serial numbers can be specified.

In standard Produmex Scan, these screens are optimized for receiving items sequentially, that is, start receiving ITEM1, enter to location, quantities or serial numbers, then start receiving ITEM2, enter location, quantities or serial numbers. This is a good solution in many cases when there are a couple of different items being received and they are grouped.

However, in this micro vertical solution the typical customer wants to receive many different items, a kind of assortment, which are not grouped by item code, maybe only by similar items. These items are also mostly serial numbered, which means the standard Produmex Scan way of receiving requires a lot of extra actions on the mobile user interface. The goal here was to allow the warehouse worker to use the bar code scanner button 99% of the time when doing the receiving. In practice this means: he will take the next piece of item (boxed), scan the item code bar code, then scan the serial number bar code, and then move on to the next piece of item (boxed).

During receipt, the items are moved to a temporary bin location, which is an empty pallet labelled with a bin code. When a pallet is full the warehouse worker can change the bin location to the next temporary bin location, the next pallet's location. In a later step, these pallets are moved to shelves with a forklift and the Produmex Scan Mass Transfer function, which moves all the stocks on one bin to another.

Comparison of the Original and New Receiving

Below you can see the original process for receiving.

The extra steps that this micro-vertical solution eliminates have been colored.

If we look at just the main action (from Set warehouse to just before Finish), receiving 10 serial items takes 10 x 5 = 50 actions this way. It needs 3 bar code scans (item, to bin, serial number) and 2 button presses (Add, Done) per item piece.

The following picture shows you the new process with these steps eliminated.

The core steps of receiving 10 items means 10 x 2 = 20 steps, plus changing the destination palette (to bin) occasionally. Even better, these actions are all bar code scans (item code, serial number), only 2 per item.

This shows how we optimized the process. Please also note, that there are other types of companies who might receive only a few different serial numbered items at once, for them, the original Produmex Scan process of scanning one item code then scanning a lot of serial numbers is much more effective.

Main Screen

Changes:

- Added Ref. No. field which will be copied to the new Delivery document. The user queries and custom fields for the above custom logic:

| Field Name | Label | Screen |

|---|---|---|

| BO_NumAtCard | Ref.No. | CreateGoodsReceiptPOScreen |

Item Lines Screen

Changes:

1. List items are changed to show Item Code + Item Name without prefix and to show bar code (EAN) in the second line instead of warehouse.

2. The warehouse is filled by the last selected warehouse for the employee by default and the value is saved if it has changed.

3. After the item has been scanned, it is checked if that item has any open Purchase Orders from the same supplier. If the item was valid and there are no problems, after scanning item code or bar code the screen automatically opens the next (bin locations) screen. No need to press the Add button explicitly.

4. The Add button checks if there is still open quantity for the given item from the same supplier. It gives a warning if there are no more open quantities.

5. UoM field is hidden because it's not used.

The user queries and custom fields for the above custom logic:

1.

User query: BXMobileWH9_CreateGoodsReceiptPOLinesScreen_DataRepeater_InternalDataLoad

-- Fill UIItem with item code and name -- and UIWarehouse with OITM.CodeBars in list SELECT SUBSTRING (S.splitdata,7,50) AS [DataRepeater.UIItem], C.CodeBars AS [DataRepeater.UIWarehouse] FROM dbo.SplitStringForDataRepeater($[DataRepeater.UIItem]) S, OITM C WHERE C.ItemCode=SUBSTRING(S.splitdata,7,PATINDEX('%*%',S.splitdata)-8)

2.

Create a new user table 'SCANEMPWH' with the following fields:

- To Bin Location (ToWH)

- Employee ID (empID)

User query: BXMobileWH9_CreateGoodsReceiptPOLinesScreen_TextWarehouse_validate_after

-- Save Warehouse value to remember it for next time IF (SELECT ISNULL([@SCANEMPWH].U_ToWH,'') FROM [@SCANEMPWH] WHERE U_empID = $[Employee.EmployeeID]) <> $[TextWarehouse] UPDATE [@SCANEMPWH] SET [U_ToWH]=$[TextWarehouse] WHERE U_empID = $[Employee.EmployeeID]

3.

User query: BXMobileWH9_CreateGoodsReceiptPOLinesScreen_TextItem_validate

-- Check Item and see if it has open quantity in Purchase orders from this supplier -- if not, show error message DECLARE @itemcode nvarchar (MAX) SET @itemcode = $[TextItem] IF NOT EXISTS SELECT (T0.ItemCode FROM OITM T0 WHERE T0.ItemCode=@itemcode) SELECT @itemcode=T1.ItemCode FROM OBCD T1 WHERE T1.BCdCode=@itemcode IF @itemcode<>'' AND (SELECT ISNULL (SUM(T1.[OpenQTX]),0) FROM OPOR T0 INNER JOIN POR1 T1 ON T0.[DocEntry] = T1.[DocEntry] WHERE T1.[ItemCode] = @itemcode AND T0.[CardCode] = LEFT($[TextSupplier],PATINDEX('%*%',$[TextSupplier])-1))=0 SELECT 'There is no Purchase Order for '+@itemcode AS 'Message$', 'E' AS 'MessageType$' ELSE SELECT '' AS dummy

User query: BXMobileWH9_CreateGoodsReceiptPOLinesScreen_TextItem_validate_after

-- If item is filled then set quantity to empty and press Add automatically IF $[TextItem]<>'' SELECT '' AS TextQuantity, 'ButtonAdd' AS Click$

4.

User query: BXMobileWH9_CreateGoodsReceiptPOLinesScreen_ButtonAdd_click

-- When add button is pressed check if there is open quantity -- for that item in Purchase Orders DECLARE @itemcode nvarchar(MAX) SET @itemcode = $[TextItem] IF NOT EXISTS (SELECT T0.ItemCode FROM OITM T0 WHERE T0.ItemCode=@itemcode) SELECT @itemcode=T1.ItemCode FROM OBVD T1 WHERE T1.BCdCode=@itemcode IF (SELECT SUM(CAST(LEFT(S.splitdata2,PATINDEX('% %',Splitdata2)-1) AS DECIMAL (1,5))) FROM dbo.SplitStringForDataRepeater2($[DataRepeater.UIItem],$[DataRepeater.UIQuantity]) S WHERE @itemcode=SUBSTRING(S.splitdata,1,PATINDEX('%*%',S.splitdatda)-1))>=(SELECT ISNULL (SUM(T1.[OpenQty]),0) FROM OPOR T0.[CardCode]=LEFT($[TextSupplier],PATINDEX('%*%',$[TextSupplier])-1)) SELECT 'There is no more PO for this item. Continue?' AS 'Message$', 'YM' AS 'MessageType$'

5.

To hide the UoM item on the screen, add a record to the Customization Fields(BXPCUSTFD) user table:

| FieldName | Visible | Screen |

|---|---|---|

| TextUoM | NO | CreateGoodsReceiptPOLinesScreen |

Serial Numbers Screen

Changes:

1. Save the last bin for next time and load it with last value

2. New field: EAN (Item's bar code) added and loaded with data

3., 4. After serial number has been scanned, automatically press the Done button to go to previous screen

The user queries and custom fields needed for these are:

1.

Create a new user table 'SCANEMPBL' with the following fields:

- To Bin Location (ToBL)

- Employee ID (empID)

User query: BXMobileWH9_CreateGoodsReceiptPOQuantitiesSerialScreen_TextBinLocation_validate_after

-- Save Bin Location from screen to employee so it can be loaded next time IF (SELECT ISNULL([@SCANEMPBL].U_ToBL,'') FROM [@SCANEMPBL] WHERE U_empID = $[Employee.EmployeeID]) <> $[TextBinLocation] UPDATE [@SCANEMPBL] SET [U_ToBL]=$[TextBinLocation] WHERE U_empID = $[Employee.EmployeeID]

1., 2.

User query: BXMobileWH9_CreateGoodsReceiptPOQuantitiesSerialScreen_Load

-- On screen load fill bin location from saved value -- and fill EAN field from OITM.CodeBars SELECT (SELECT [@SCANEMPBL].U_ToBL FROM [@SCANEMPBL] WHERE U_empID = $[Employee.EmployeeID]) AS 'TextBinLocation', (SELECT CodeBars FROM OITM WHERE ItemCode=SUBSTRING($[TextItem],1,PATINDEX('%*%',$[TextItem])-2) ) AS 'EanCode'

2.

To show the new EAN field on the screen, add a record to the Customization Fields(BXPCUSTFD) user table:

| FieldName | Label | ReadOnly | Screen |

|---|---|---|---|

| EanCode | EAN | YES | CreateGoodsReceiptPOQuantitiesSerialScreen |

3., 4.

User query: BXMoblieWH9_CreateGoodsReceiptPOQuantitiesSerialScreen_TextSerial_validate_after

-- After the serial number has been scanned, -- press OK button to go back to previous screen IF $[TextSerial]<>'' SELECT 'OK' AS Click$

3.1.5. Regular Items Screen

Changes:

1. New field: EAN (Item's bar code) added and loaded with data

2. Save the last bin for next time and load it with last value

3. Set quantity to 1 by default and focus on quantity

4., 5. When the Add button is pressed automatically press Done to go back to previous screen

6. UoM field is hidden because it's not used

The user queries and custom fields needed for these are:

1., 2., 3.

Create a new user table 'SCANEMPBL' with the following fields:

- To Bin Location (ToBL)

- Employee ID (empID)

User query: BXMobileWH9_CreateGoodsReceiptPOQuantitiesNormalScreen_Load

-- When screen is loaded fill bin location with last value -- fill EAN with bar code from OITM, set quantit to 1 and -- focus on Quantity field SELECT (SELECT CodeBars FROM OITM WHERE ItemCode=SUBSTRING($[TextItem],1,PATINDEX('%*%',$[TextItem])-2) ) AS 'EanCode', (SELECT [@SCANEMPBL].U_ToBL FROM [@SCANEMPBL] WHERE U_empID = $[Employee.EmployeeID]) AS 'TextBinLocation', '1' AS 'TextQuantity', 'TextQuantity' AS Click$

2.

User query: BXMobileWH9_CreateGoodsReceiptPOQuantitiesNormalScreen_TextBinLocation_validate_after

-- Save bin location for next time IF (SELECT ISNULL([@SCANEMPBL].U_ToBL,'') FROM [@SCANEMPBL] WHERE U_empID = $[Employee.EmployeeID]) <> $[TextBinLocation] UPDATE [@SCANEMPBL] SET [U_ToBL]=$[TextBinLocation] WHERE U_empID = $[Employee.EmployeeID]

4., 5.

User query: BXMobileWH9_CreateGoodsReceiptPOQuantitiesNormalScreen_ButtonAdd_click_after

-- When Add button is pressed, automatically press OK to close screen SELECT 'OK' AS Click$

2., 6.

To show the new EAN field on the screen and hide UoM, add record to the Customization Fields(BXPCUSTFD) user table:

| FieldName | Label | ReadOnly | Visible | Screen |

|---|---|---|---|---|

| EanCode | EAN | YES | YES | CreateGoodsReceiptPOQuantitiesNormalScreen |

| TextUoM | NO | CreateGoodsReceiptPOQuantitiesNormalScreen |

Helper SQL procedures

Produmex Scan List splitting 1

CREATE FUNCTION [dbo]. [SplitStringForDataRepeater] ( @string NVARCHAR (MAX)) RETURNS @output TABLE (splitdata NVARCHAR (MAX)) BEGIN DECLARE @START INT, @END INT SELECT @START = 1, @END = CHARINDEX ('##', @string) WHILE @START < LEN (@string) + 1 BEGIN IF @END = 0 SET @END = LEN (@string) + 2 INSERT INTO @output (splitdata) VALUES (SUBSTRING(@string, @START, @END - @START)) SET @START = @END + 2 SET @END = CHARINDEX('##', @string, @START) END RETURN END

Produmex Scan List splitting 2

CREATE FUNCTION [dbo]. [SplitStringForDataRepeater2] ( @string NVARCHAR (MAX), @string2 NVARCHAR (MAX)) RETURNS @output TABLE (splitdata NVARCHAR (MAX), splitdata2 NVARCHAR (MAX)) BEGIN DECLARE @START INT, @END INT @start2 INT, @end2 INT SELECT @START = 1, @END = CHARINDEX ('##', @string) , @start2 = 1, @end2 = CHARINDEX ('##', @string2) WHILE @START < LEN (@string) + 1 BEGIN IF @END = 0 BEGIN SET @END = LEN (@string) + 2 SET @end2 = LEN (@string) + 2 END INSERT INTO @output (splitdata, splitdata2) VALUES (SUBSTRING(@string, @START, @END - @START) ,SUBSTRING(@string2, @start2, @end2 - @start2)) SET @START = @END + 2 SET @END = CHARINDEX('##', @string, @START) SET @start2 = @end2 + 2 SET @END = CHARINDEX('##', @string2, @start2) END RETURN END

Customizing serial number management in Produmex Scan

This document provides examples for serial number management customization in Produmex Scan. For more information about the general customization method please see: Customization Technology in Produmex Scan

User-Defined Fields

Goods Receipt

Goods Receipt PO Lines Screen

Add the following record to the Customization Fields user table:

| FieldName | Visible | Screen |

|---|---|---|

| TextUoM | NO | GoodsReceiptPOLinesScreen |

Item code field must be scanned before Add button click

Query name: BXMobileWH9_GoodsReceiptPOLinesScreen_ButtonAdd_click

IF $[TextItem] ='' SELECT 'You must scan an item first!' AS 'Message$', 'E' AS 'MessageType$', 'TextItem' AS Click$

Item code field must be scanned before Update button click

Query name: BXMobileWH9_GoodsReceiptPOLinesScreen_ButtonUpdate_click

IF $[TextItem] ='' SELECT 'Please scan an item!' AS 'Message$', 'E' AS 'MessageType$', 'TextItem' AS Click$

Focus on Item field (when returning to this screen)

Query name: BXMobileWH9_GoodsReceiptPOLinesScreen_Activate

SELECT 'TextItem' AS Click$

Change contents of the list, show bar code instead of WH text

Query name: BXMobileWH9_GoodsReceiptPOLinesScreen_DataRepeater_InternalDataLoad

SELECT SUBSTRING(S.splitdata,1,50) AS [DataRepeater.UIItemCode], C.CodeBars AS [DataRepeater.UIWarehouse] FROM dbo.SplitStringForDataRepeater($[DataRepeater.UIItemCode]) S, OITM C WHERE C.ItemCode=SUBSTRING(S.splitdata,1,PATINDEX('%*%',S.splitdata)-2)

After Item field has been entered write ' ' to quantity and press Add button

Query name: BXMobileWH9_GoodsReceiptPOLinesScreen_TextItem_validate_after

IF $[TextItem]<>'' SELECT '' AS TextQuantity, 'ButtonAdd' AS Click$

Goods Receipt PO Quantities Serial Screen

Add the following record to the Customization Fields user table:

| FieldName | Label | ReadOnly | Screen |

|---|---|---|---|

| EanCode | EAN | YES | GoodsReceiptPOQuantitiesSerialScreen |

Create a new user table ‘SCANEMPBL’ with the following fields:

- Employee ID (empID)

- To Bin Location (ToBL)

Load bin location for employee, fill EanCode with bar code

Query name: BXMobileWH9_GoodsReceiptPOQuantitiesSerialScreen_Load

SELECT (SELECT [@SCANEMPBL].U_ToBL FROM [@SCANEMPBL] WHERE U_empID = $[Employee.EmployeeID]) AS 'TextBinLocation', (SELECT CodeBars FROM OITM WHERE ItemCode=SUBSTRING($[TextItem],1,PATINDEX('%*%',$[TextItem])-2) ) AS 'EanCode'

Save the Bin Location value for next time

Query name: BXMobileWH9_GoodsReceiptPOQuantitiesSerialScreen_TextBinLocation_validate_after

IF (SELECT ISNULL(OHEM.U_ToBL,'') FROM OHEM WHERE empID = $[Employee.EmployeeID]) <> $[TextBinLocation] UPDATE OHEM SET [U_ToBL]=$[TextBinLocation] WHERE empID = $[Employee.EmployeeID]

After serial number was specified press OK to go back

Query name: BXMobileWH9_GoodsReceiptPOQuantitiesSerialScreen_TextSerial_validate_after

IF $[TextSerial]<>'' SELECT 'OK' AS Click$

Goods Receipt PO Quantities Normal Screen

Add the following record to the Customization Fields user table:

| FieldName | Label | ReadOnly | Screen |

|---|---|---|---|

| EanCode | EAN | YES | GoodsReceiptPOQuantitiesNormalScreen |

| FieldName | Visible | Screen | |

| TextUoM | NO | GoodsReceiptPOQuantitiesNormalScreen | |

Create a new user table ‘SCANEMPBL’ with the following fields:

- Employee ID (empID)

- To Bin Location (ToBL)

Save the Bin Location value for next time

Query name: BXMobileWH9_GoodsReceiptPOQuantitiesNormalScreen_TextBinLocation_validate_after

IF (SELECT ISNULL([@SCANEMPBL].U_ToBL,'') FROM [@SCANEMPBL] WHERE U_empID = $[Employee.EmployeeID]) <> $[TextBinLocation] UPDATE [@SCANEMPBL] SET [U_ToBL]=$[TextBinLocation] WHERE U_empID = $[Employee.EmployeeID]

Load last location for employee, EAN bar code, set quantity to 1 and focus on quantity

Query name: BXMobileWH9_GoodsReceiptPOQuantitiesNormalScreen_Load

SELECT (SELECT CodeBars FROM OITM WHERE ItemCode=SUBSTRING($[TextItem],1,PATINDEX('%*%',$[TextItem])-2) ) AS 'EanCode', (SELECT [@SCANEMPBL].U_ToBL FROM [@SCANEMPBL] WHERE U_empID = $[Employee.EmployeeID]) AS 'TextBinLocation', '1' AS 'TextQuantity' ,'TextQuantity' AS Click$

After the Add button press OK to go back

Query name: BXMobileWH9_GoodsReceiptPOQuantitiesNormalScreen_ButtonAdd_click_after

SELECT 'OK' AS Click$

Free Goods Receipt

CreateGoodsReceiptPOLinesScreen

Add the following record to the Customization Fields user table:

| FieldName | Visible | Screen |

|---|---|---|

| TextUoM | NO | GoodsReceiptReceiptLinesScreen |

Create a new user table ‘SCANEMPWH’ with the following fields:

- Employee ID (empID)

- To Warehouse (ToWh)

Load saved warehouse for employee, focus on item

Query name: BXMobileWH9_CreateGoodsReceiptPOLinesScreen_Load

SELECT (SELECT [@SCANEMPWH].U_ToWh FROM [@SCANEMPWH] WHERE U_empID = $[Employee.EmployeeID]) AS 'TextWarehouse', 'TextItem' AS Click$

Focus on item (after returning to this screen) Query name: BXMobileWH9_CreateGoodsReceiptPOLinesScreen_Activate

SELECT 'TextItem' AS Click$

Modify list contents

Query name: BXMobileWH9_CreateGoodsReceiptPOLinesScreen_DataRepeater_InternalDataLoad

-- Modify list contents: -- [DataRepeater.UIItem] Item code + name -- [DataRepeater.UIWarehouse] Bar code (EAN) SELECT SUBSTRING(S.splitdata,7,50) AS [DataRepeater.UIItem], C.CodeBars AS [DataRepeater.UIWarehouse] FROM dbo.SplitStringForDataRepeater($[DataRepeater.UIItem]) S, OITM C WHERE C.ItemCode=SUBSTRING(S.splitdata,7,PATINDEX('%*%',S.splitdata)-8)

Save warehouse for employee

Query name: BXMobileWH9_CreateGoodsReceiptPOLinesScreen_TextWarehouse_validate_after

IF (SELECT ISNULL([@SCANEMPWH].U_ToWh,'') FROM [@SCANEMPWH] WHERE U_empID = $[Employee.EmployeeID]) <> $[TextWarehouse] UPDATE [@SCANEMPWH] SET [U_ToWh]=$[TextWarehouse] WHERE U_empID = $[Employee.EmployeeID]

Check if item has been ordered/open quantity from this supplier

Query name: BXMobileWH9_CreateGoodsReceiptPOLinesScreen_TextItem_validate

DECLARE @itemcode nvarchar(MAX) SET @itemcode = $[TextItem] IF NOT EXISTS (SELECT T0.ItemCode FROM OITM T0 WHERE T0.ItemCode=@itemcode) SELECT @itemcode=T1.ItemCode FROM OBCD T1 WHERE T1.BcdCode=@itemcode IF @itemcode<>'' AND (SELECT ISNULL(SUM(T1.[OpenQty]),0) FROM OPOR T0 INNER JOIN POR1 T1 ON T0.[DocEntry] = T1.[DocEntry] WHERE T1.[ItemCode] =@itemcode AND T0.[CardCode] = LEFT($[TextSupplier],PATINDEX('%*%',$[TextSupplier])-1))=0 SELECT 'There is no Purchase Order: '+ @itemcode AS 'Message$', 'E' AS 'MessageType$' ELSE SELECT '' AS dummy

Check if item has been ordered/open quantity from this supplier

Query name: BXMobileWH9_CreateGoodsReceiptPOLinesScreen_TextItem_validate

DECLARE @itemcode nvarchar(MAX) SET @itemcode = $[TextItem] IF NOT EXISTS (SELECT T0.ItemCode FROM OITM T0 WHERE T0.ItemCode=@itemcode) SELECT @itemcode=T1.ItemCode FROM OBCD T1 WHERE T1.BcdCode=@itemcode IF @itemcode<>'' AND (SELECT ISNULL(SUM(T1.[OpenQty]),0) FROM OPOR T0 INNER JOIN POR1 T1 ON T0.[DocEntry] = T1.[DocEntry] WHERE T1.[ItemCode] =@itemcode AND T0.[CardCode] =LEFT($[TextSupplier],PATINDEX('%*%',$[TextSupplier])-1))=0 SELECT 'There is no Purchase Order: '+ @itemcode AS 'Message$', 'E' AS 'MessageType$' ELSE SELECT '' AS dummy

After item code has been entered write ' ' to quantity and press Add

Query name: BXMobileWH9_CreateGoodsReceiptPOLinesScreen_TextItem_validate_after

IF $[TextItem]<>'' SELECT '' AS TextQuantity, 'ButtonAdd' AS Click$

CreateGoodsReceiptPOQuantitiesSerialScreen

Add the following record to the Customization Fields user table:

| FieldName | Label | ReadOnly | Screen |

|---|---|---|---|

| EanCode | EAN | YES | CreateGoodsReceiptPOQuantitiesSerialScreen |

Create a new user table ‘SCANEMPBL’ with the following fields: • Employee ID (empID) • To Warehouse (ToBL)

Load bin location from employee, fill EAN bar code

Query name: BXMobileWH9_CreateGoodsReceiptPOQuantitiesSerialScreen_Load

SELECT (SELECT [@SCANEMPBL].U_ToBL FROM [@SCANEMPBL] WHERE U_empID = $[Employee.EmployeeID]) AS 'TextBinLocation', (SELECT CodeBars FROM OITM WHERE ItemCode=SUBSTRING($[TextItem],1,PATINDEX('%*%',$[TextItem])-2) ) AS 'EanCode'

Save bin location to employee

Query name: BXMobileWH9_CreateGoodsReceiptPOQuantitiesSerialScreen_TextBinLocation_validate_after

IF (SELECT ISNULL([@SCANEMPBL].U_ToBL,'') FROM [@SCANEMPBL] WHERE U_empID = $[Employee.EmployeeID]) <> $[TextBinLocation] UPDATE [@SCANEMPBL] SET [U_ToBL]=$[TextBinLocation] WHERE U_empID = $[Employee.EmployeeID]

After serial entry press OK to go back

Query name: BXMobileWH9_CreateGoodsReceiptPOQuantitiesSerialScreen_TextSerial_validate_after

IF $[TextSerial]<>'' SELECT 'OK' AS Click$

CreateGoodsReceiptPOQuantitiesNormalScreen

Add the following record to the Customization Fields user table:

| FieldName | Label | ReadOnly | Screen |

|---|---|---|---|

| EanCode | EAN | YES | GoodsReceiptPOQuantitiesNormalScreen |

| FieldName | Visible | Screen | |

| TextUoM | NO | GoodsReceiptPOQuantitiesNormalScreen | |

Create a new user table ‘SCANEMPBL’ with the following fields:

- Employee ID (empID)

- To Warehouse (ToBL)

Load last location for employee, EAN bar code, set quantity to 1 and focus on quantity

Query name: BXMobileWH9_CreateGoodsReceiptPOQuantitiesNormalScreen_Load

SELECT (SELECT CodeBars FROM OITM WHERE ItemCode=SUBSTRING($[TextItem],1,PATINDEX('%*%',$[TextItem])-2) ) AS 'EanCode', (SELECT [@SCANEMPBL].U_ToBL FROM [@SCANEMPBL] WHERE U_empID = $[Employee.EmployeeID]) AS 'TextBinLocation', '1' AS 'TextQuantity' ,'TextQuantity' AS Click$

Save bin location to employee

Query name: BXMobileWH9_CreateGoodsReceiptPOQuantitiesNormalScreen_TextBinLocation_validate_after

IF (SELECT ISNULL([@SCANEMPBL].U_ToBL,'') FROM [@SCANEMPBL] WHERE U_empID = $[Employee.EmployeeID]) <> $[TextBinLocation] UPDATE [@SCANEMPBL] SET [U_ToBL]=$[TextBinLocation] WHERE U_empID = $[Employee.EmployeeID]

After add button press OK to go back

Query name: BXMobileWH9_CreateGoodsReceiptPOQuantitiesNormalScreen_ButtonAdd_click_after

SELECT 'OK' AS Click$

Transfer Stocks

TransferStocksScreen

Add the following record to the Customization Fields user table:

| FieldName | Visible | Screen |

|---|---|---|

| TextBatch | NO | CreateGoodsReceiptPOQuantitiesSerialScreen |

Modify the list contents: show EAN bar code instead of item code

Query name: BXMobileWH9_TransferStocksScreen_DataRepeater_InternalDataLoad

SELECT SUBSTRING(S.splitdata,1,15)+'EAN:'+ ISNULL(C.CodeBars,'') AS [DataRepeater.UIItemCode] FROM dbo.SplitStringForDataRepeater($[DataRepeater.UIItemCode]) S, OITM C WHERE C.ItemCode=SUBSTRING(S.splitdata,1,PATINDEX('%*%',S.splitdata)-2)

Focus on item field after returning to this screen

Query name: BXMobileWH9_TransferStocksScreen_Activate

SELECT 'TextItem' AS Click$

TransferStocksQuantitiesSerialScreen

Add the following record to the Customization Fields user table:

| FieldName | Label | ReadOnly | Screen |

|---|---|---|---|

| EanCode | EAN | YES | TransferStocksQuantitiesSerialScreen |

Create a new user table ‘SCANEMPBL’ with the following fields:

- Employee ID (empID)

- To Bin Location (ToBL)

Fill to location from saved, load bar code into EAN code

Query name: BXMobileWH9_TransferStocksQuantitiesSerialScreen_Load

SELECT (SELECT [@SCANEMPBL].U_ToBL FROM [@SCANEMPBL] WHERE U_empID = $[Employee.EmployeeID]) AS 'TextToLocation', (SELECT CodeBars FROM OITM WHERE ItemCode=SUBSTRING($[TextItem],1,PATINDEX('%*%',$[TextItem])-2) ) AS 'EanCode'

Save to location for employee

Query name: BXMobileWH9_TransferStocksQuantitiesSerialScreen_TextToLocation_validate_after

IF (SELECT ISNULL([@SCANEMPBL].U_ToBL,'') FROM [@SCANEMPBL] WHERE U_empID = $[Employee.EmployeeID]) <> $[TextToLocation] UPDATE [@SCANEMPBL] SET [U_ToBL]=$[TextToLocation] WHERE U_empID = $[Employee.EmployeeID]

After serial number entered, press OK to go back

Query name: BXMobileWH9_TransferStocksQuantitiesSerialScreen_TextSerialNumber_validate_after

IF $[TextSerialNumber]<>'' SELECT 'OK' AS Click$

TransferStocksQuantitiesNormalScreen

Add the following record to the Customization Fields user table:

| FieldName | Label | ReadOnly | Screen |

|---|---|---|---|

| EanCode | EAN | YES | TransferStocksQuantitiesNormalScreen |

| FieldName | Visible | Screen | |

| TextUoM | NO | TransferStocksQuantitiesNormalScreen | |

Create a new user table ‘SCANEMPBL’ with the following fields:

- Employee ID (empID)

- To Warehouse (ToBL)

Load EAN bar code and to location, set quantity to 1 and focus on quantity

Query name: BXMobileWH9_TransferStocksQuantitiesNormalScreen_Load

SELECT (SELECT CodeBars FROM OITM WHERE ItemCode=SUBSTRING($[TextItem],1,PATINDEX('%*%',$[TextItem])-2) ) AS 'EanCode', (SELECT [@SCANEMPBL].U_ToBL FROM [@SCANEMPBL] WHERE U_empID = $[Employee.EmployeeID]) AS 'TextToLocation','1' AS 'TextQuantity','TextQuantity' AS Click$

Save to location for employee

Query name: BXMobileWH9_TransferStocksQuantitiesNormalScreen_TextToLocation_validate_after

IF (SELECT ISNULL([@SCANEMPBL].U_ToBL,'') FROM [@SCANEMPBL] WHERE U_empID = $[Employee.EmployeeID]) <> $[TextToLocation] UPDATE [@SCANEMPBL] SET [U_ToBL]=$[TextToLocation] WHERE U_empID = $[Employee.EmployeeID]

Press OK to go back after Add button

Query name: BXMobileWH9_TransferStocksQuantitiesNormalScreen_ButtonAdd_click_after

SELECT 'OK' AS Click$

Mass Transfer

TransferStocksMassScreen

Create a new user table ‘SCANEMPBL’ with the following fields:

- Employee ID (empID)

- To Bin Location (ToBL)

- From Bin Location (FromBL)

Load saved bin location from and to

Query name: BXMobileWH9_TransferStocksMassScreen_Load

SELECT (SELECT [@SCANEMPBL].U_FromBL FROM [@SCANEMPBL] WHERE U_empID = $[Employee.EmployeeID]) AS 'TextWHBinLocationFrom', (SELECT [@SCANEMPBL].U_ToBL FROM [@SCANEMPBL] WHERE U_empID = $[Employee.EmployeeID]) AS 'TextWHBinLocationTo'

Save from bin location

Query name: BXMobileWH9_TransferStocksMassScreen_TextWHBinLocationFrom_validate_after

IF $[TextWHBinLocationFrom] <>'' AND (SELECT ISNULL([@SCANEMPBL].U_FromBL,'') FROM [@SCANEMPBL] WHERE U_empID = $[Employee.EmployeeID]) <> $[TextWHBinLocationFrom] UPDATE [@SCANEMPBL] SET [U_FromBL]=$[TextWHBinLocationFrom] WHERE U_empID = $[Employee.EmployeeID]

Save to bin location

Query name: BXMobileWH9_TransferStocksMassScreen_TextWHBinLocationFrom_validate_after

IF $[TextWHBinLocationTo] <>'' AND (SELECT ISNULL([@SCANEMPBL].U_ToBL,'') FROM [@SCANEMPBL] WHERE U_empID =$[Employee.EmployeeID]) <> $[TextWHBinLocationTo] UPDATE [@SCANEMPBL] SET [U_ToBL]=$[TextWHBinLocationTo] WHERE U_empID = $[Employee.EmployeeID]

Modify list contents

• [DataRepeater. UIItemCode] Item code + name

• [DataRepeater.UIOnHandQuantity] Bar code (EAN) + quantity

Query name: BXMobileWH9_TransferStocksMassScreen_DataRepeater_InternalDataLoad

-- Modify list contents -- [DataRepeater. UIItemCode] Item code + name -- [DataRepeater.UIOnHandQuantity] Bar code (EAN) + quantity SELECT C.CodeBars + ' ' +SUBSTRING(S.splitdata2,1,50) AS [DataRepeater.UIOnHandQuantity] FROM dbo.SplitStringForDataRepeater2($[DataRepeater.UIItemCode], $ [DataRepeater.UIOnHandQuantity]) S, OITM C WHERE C.ItemCode=SUBSTRING(S.splitdata,1,PATINDEX('%*%',S.splitdata)-1)

Transfer Stock Request

TransferStockRequestLineScreen

Add the following record to the Customization Fields user table:

| FieldName | Visible | Screen |

|---|---|---|

| TextBatch | NO | TransferStockRequestLineScreen |

Modify list contents, add EAN bar code

Query name: BXMobileWH9_TransferStockRequestLineScreen_DataRepeater_InternalDataLoad

SELECT SUBSTRING(S.splitdata,7,15)+' EAN:'+ ISNULL(C.CodeBars,'') AS [DataRepeater.UIItem] FROM dbo.SplitStringForDataRepeater($[DataRepeater.UIItem]) S, OITM C WHERE C.ItemCode=SUBSTRING(S.splitdata,7,PATINDEX('%*%',S.splitdata)-8)

After Item Code has been entered, set quantity to ' ' and press Add

Query name: BXMobileWH9_TransferStockRequestLineScreen_TextItem_validate_after

IF $[TextItem]<>'' SELECT '' AS TextQuantity, 'ButtonAdd' AS Click$

Item code scanning is mandatory (before pressing Add button)

Query name: BXMobileWH9_TransferStockRequestLineScreen_ButtonAdd_click

IF $[TextItem] ='' SELECT 'You must scan an item!' AS 'Message$', 'E' AS 'MessageType$', 'TextItem' AS Click$

Item code scanning is mandatory (before pressing Update button)

Query name: BXMobileWH9_TransferStockRequestLineScreen_ButtonUpdate_click

IF $[TextItem] ='' SELECT 'You must scan an item!' AS 'Message$', 'E' AS 'MessageType$', 'TextItem' AS Click$

Focus on Item field (when returning to this screen)

Query name: BXMobileWH9_TransferStockRequestLineScreen_Activate

SELECT 'TextItem' AS Click$

4.1.5.2. TransferStockRequestsQuantitiesSerialScreen

Add the following record to the Customization Fields user table:

| FieldName | Label | ReadOnly | Screen |

|---|---|---|---|

| EanCode | EAN | YES | TransferStockRequestsQuantitiesSerialScreen |

Create a new user table ‘SCANEMPBL’ with the following fields:

- Employee ID (empID)

- To Bin Location (ToBL)

Set to location from saved, set EAN code from barcode

Query name: BXMobileWH9_TransferStockRequestsQuantitiesSerialScreen_Load